Purpose-built drive solutions for African mining

SEW-Eurodrive’s National Sales and Marketing Manager, Jonathan McKey highlights some of the company’s customised solutions for the African mining industry and the lead time advantages offered by the new multimillion local assembly facility in Johannesburg.

SEW-Eurodrive offers a wide range of purpose-built adaptable drive solutions to best suit the specific needs of equipment operating on African mines. “We supply innovative, high quality and premium efficiency drive products. In addition, through a significantly larger local stock holding and our expanded local assembly capability, we can now deliver solutions with the shortest lead times available on the African continent,” says Jonathan McKey, the company’s National Sales and Marketing Manager.

“Also, most of the accessories that are needed for these drive solutions, such as brakes, oil pumps and encoders, are also supplied, many of which are not add-on components from sub-suppliers,” adds McKey.

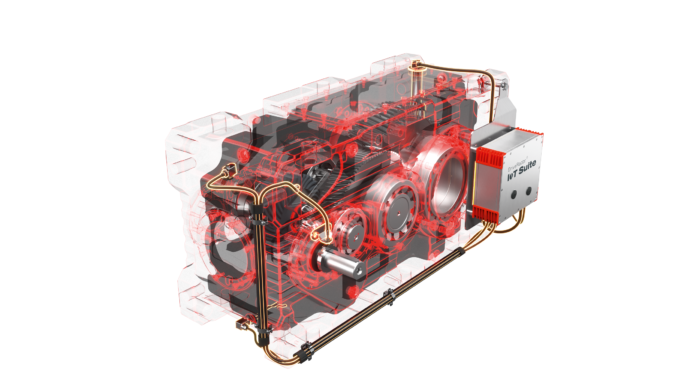

Citing some key examples, McKey begins with SEW-Eurodrive’s flagship New Generation X.e Series Industrial Gearboxes (IGs). “X.e Series IGs offer robust, reliable, efficient and easy to maintain modular solutions that are ideal for the harsh environments on African mines,” he says. The stockholding of possible torque/speed combinations and fine-size graduations have been significantly increased to make the X.e Series easy to customise to precisely meet the needs of applications such as mine conveyors or mill drives.

Additional modular features and options, such as motor adapters, backstops, various sealing and shaft systems and many more, also add to their ease of use and reliability.

SEW-Eurodrive’s large open segmented girth gears comprise of precision-manufactured cast ductile individual segments that simplify handling, transportation and onsite assembly, as well as strength and hardness for longer lasting reliability. This allows complete drive systems to be easily shipped to site in standard containers, while also simplifying onsite assembly, which can be done far more quickly and with lighter lifting equipment.

While girth gears are the core component of mill drives and rotary scrubbers, SEW-Eurodrive supplies total mill drive solutions and power packs, which typically include a large electric motor and Industrial Gears to turn the external pinion that drives the girth gear.

In support of the reliability of mine equipment, SEW-Eurodrive can also install its DriveRadar® predictive maintenance management solution. “DriveRadar® automatically records and analyses operational data from our industrial gear units and uses it to track equipment condition in real time and predict performance changes,” McKey explains.

Describing the SEW-Eurodrive offering for high torque mining applications such as bulk materials handling systems and apron feeder drives on conveying systems, McKey notes that the planetary P-series Industrial Gears are coupled with primary gear units to offer compact and cost-effective solutions with high thermal ratings.

In addition, for many variable torque processing plant drive applications such as conveyors, pumps, extractor fans, bucket and chain elevators, hoists and lifting systems, travel drives and mixers, a comprehensive range of gearmotors and large industrial gear solutions are available in numerous sizes and ratios.

SEW-Eurodrive’s MOVIMOT® and MoviC solutions deliver gearmotors with integrated frequency inverters for applications that require an easily implementable variable speeds and special automated functionality.

Concluding, McKey says that the company is currently delivering on a R200-million investment in the expanded South African facility, which will enable SEW-EURODRIVE South Africa to look after another 24 facilities in different African countries.